Harnessing solar power for sustainable agroforestry: An automated phototactic device to control insect pests

31/10/2025TN&MTIn line with the global shift toward green and sustainable agriculture, the use of renewable energy in production has become essential for reducing emissions and protecting ecosystems. A research team including Nguyen Van Giap, Bui Duy Ngoc, Nguyen Trong Tuan, Cao Chi Cong, Le Thi Hung, To Quoc Huy, Nguyen Van Minh, and Pham Dinh Manh from the Forest Industry Research Institute, Vietnam Academy of Forest Sciences and Thanh Do University, has successfully developed an intelligent control and solar charging system for a phototactic device designed to control insect pests in agricultural and forestry crops.

The system integrates an STM32F103-based microcontroller, a dual-axis sun-tracking mechanism, and remote control via GSM, enabling fully automated operation, optimized solar energy harvesting, and stable performance under outdoor conditions.

Clean energy: A solution for pest control in agriculture

As Vietnam’s agriculture advances toward sustainability, reducing the use of chemical pesticides has become a top priority. Studies have shown that pesticide residues in soil, water, and air not only reduce crop yield and quality but also threaten human health and biodiversity. Hence, the search for physical and environmentally friendly alternatives is attracting growing attention from research institutes, universities, and agricultural enterprises.

Among promising approaches is the use of phototactic pest control devices - systems that attract insects using ultraviolet light and eliminate them through high-voltage discharge. These devices avoid chemical inputs, prevent pest resistance, and minimize ecological impacts. They operate autonomously, particularly at night when insect activity peaks.

However, in remote or off-grid agricultural areas, such devices face practical limitations. Most current models employ simple control circuits without automatic protection or power optimization, resulting in low efficiency, short lifespan, and high maintenance costs. The lack of a stable power source also restricts operation time, often requiring manual battery charging, which limits large-scale deployment.

To address these challenges, the research team launched the study entitled “Design of control circuit and charging system from solar battery for photosolar devices to prevent insects that damage agricultural and forestry crops.” The objective was not only to overcome technical constraints but also to develop a self-sustaining clean-energy model suitable for agricultural and forestry production.

According to the researchers, integrating solar energy into agricultural devices offers dual benefits: reducing operational costs and cutting greenhouse gas emissions, aligning with Vietnam’s national strategy for green transition and circular agriculture. Solar energy is abundant, renewable, and particularly suited to rural and mountainous regions with high solar irradiance but limited access to grid electricity.

The study was built on three core principles:

- Automation of device operation, enabling self-regulated on/off cycles without manual intervention.

- Optimization of solar energy utilization through a dual-axis sun-tracking charging station that maximizes energy capture.

- Enhanced durability and adaptability to field conditions, including harsh weather and uneven terrain.

Rather than merely improving the lamp-trap design, this research developed a comprehensive control and charging system, forming a scalable solution for low-power agricultural and forestry applications.

Intelligent control and sun-tracking system: A technological leap toward field application

The system consists of two key components: An intelligent control circuit and a solar charging station equipped with dual-axis sun tracking. These components operate synchronously, ensuring the phototactic device can function reliably throughout the night without dependence on the power grid.

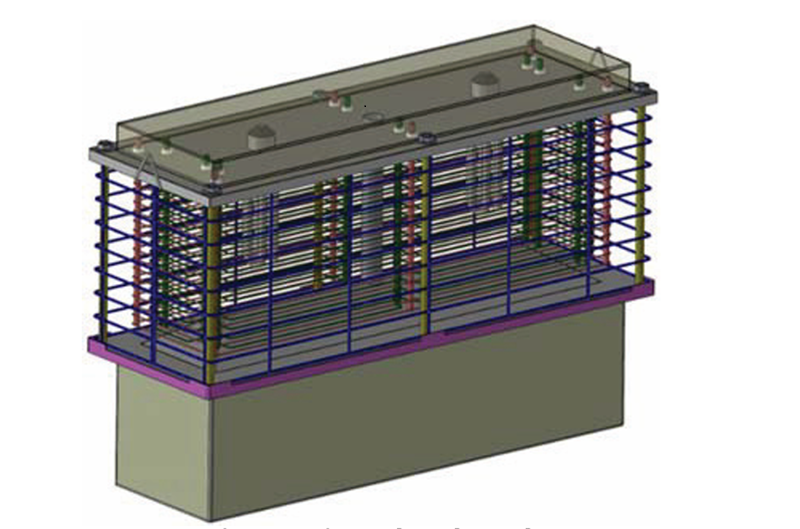

Overall design of the phototactic pest control device

The control circuit: the “brain” of the system

The control unit is built around the STM32F103 microcontroller, recognized for its high processing capability and low energy consumption. It operates in two modes:

- Automated timer mode: The device automatically activates the UV lamp and high-voltage grid during peak insect activity and shuts down according to preset cycles.

- Remote GSM control mode: Users can send SMS commands to switch the device on or off in case of storms or other unexpected events, ensuring flexible and safe operation.

The system can generate up to 5 kV of high voltage for insect elimination, with built-in protections against overload, deep discharge, and overheating. A 12 V DC battery is converted via an inverter to 220 V AC for the UV lamp, while the high-voltage module supplies DC pulses to the grid for pest destruction.

The solar charging station: maximizing energy efficiency

The solar charging station ensures the device’s energy autonomy. Unlike fixed models, this design features a dual-axis tracking mechanism:

- The East–West axis follows the sun’s daily movement.

- The North–South axis adjusts seasonally to maintain optimal orientation.

This design keeps the panels perpendicular to sunlight throughout the day, increasing energy harvesting efficiency by 20–40% compared with fixed systems. The charge controller operates across a wide voltage range (5–42 V) and supports multiple battery types.

Under high irradiance conditions, a single station can charge up to four or five devices simultaneously, ensuring full battery capacity before nighttime operation. The controller incorporates reverse polarity protection, overcharge prevention, and automatic cut-off to extend system lifespan and ensure safety.

When integrated, the control circuit and charging station enable a fully automated operational cycle – charging by day and pest control by night, with optional remote management. This design reduces labor costs and demonstrates the potential of renewable energy in agricultural mechanization.

From laboratory to field: Refining a clean-energy model

To translate the concept into practice, the research team followed a rigorous workflow of design, simulation, fabrication, and field testing, combining theoretical modeling with real-world validation.

The mechanical frame, sun-tracking structure, and circuit layout were first modeled using AutoCAD, SolidWorks, and Altium Designer. After simulation, a prototype charging station was fabricated from lightweight, corrosion-resistant aluminum alloy, fitted with photovoltaic panels of approximately 18% conversion efficiency. Light sensors positioned in four directions detect solar angles and automatically adjust the panel’s orientation.

The STM32F103 control module was programmed and connected to GSM, voltage, and current sensors to monitor real-time charging parameters.

Field experiments were conducted under summer (high irradiance) and winter (low irradiance, short daylight) conditions to evaluate performance and stability. Results confirmed that sun tracking increased energy capture by 20–40%, maintaining stable output voltage and preventing overheating or voltage drop during extended operation.

Protective circuits against overloading, deep discharge, and overcharging functioned effectively, ensuring battery longevity. The GSM module proved particularly useful for remote operation in mountainous areas where on-site access is limited.

According to the research team, these trials provided key data for optimizing control algorithms, enhancing mechanical stability, and preparing for technology transfer to production partners.

Advancing solar-powered agriculture and forestry

The successful development of this intelligent control and charging system represents a notable step forward in promoting automation and renewable energy integration within Vietnam’s agricultural and forestry sectors.

By enabling devices to operate independently of the power grid, the system provides a cost-effective, low-emission, and sustainable solution for pest management. The combination of clean energy and smart control technology reduces operating costs and greenhouse gas emissions while strengthening the resilience of agricultural production systems.

Beyond pest control, the same platform can be adapted for other smart farming applications such as micro-weather monitoring, automatic irrigation, or environmental sensing. Each solar-powered device represents a tangible step toward Vietnam’s green transition and net-zero emission goals under COP26 commitments.

Following successful trials, the research team plans to refine control algorithms, miniaturize circuit design, and enhance the durability of the sun-tracking frame for wider deployment. The system is expected to be transferred to agricultural engineering enterprises and forestry cooperatives for application in off-grid areas.

By integrating renewable energy, intelligent control, and practical usability, this research opens a new direction for sustainable agriculture where technology and environmental stewardship work hand in hand to build a greener future.

Minh Thao

Source: Based on the research project “Research results on design of control circuit and charging system from solar battery for photosolar devices to prevent insects that damage agricultural and forestry crops conducted by Nguyen Van Giap, Bui Duy Ngoc, Nguyen Trong Tuan, Cao Chi Cong, Le Thi Hung, To Quoc Huy, Nguyen Van Minh, and Pham Dinh Manh from the Forest Industry Research Institute, Vietnam Academy of Forest Sciences and Thanh Do University